I have received many enquiries bout the repetitive "grinding" noise one can here in the post; Sunday, January 4, 2015.

Well, glad you ask, and now take a seat and get prepared to be bored to tears.......

The Hydropneumatic (no it's not air) suspension that Citroen developed in the 40's and that saw it's full deployment in all its glory in 1955 on the Citroen DS (like the one in this Blog), was a true marvel of engineering; that it also powered the brakes, power-steering (yes, in 1955) and c-matic (manual-clutchless transmission) adds to its awe.

It is a constant flow system, that is, the pump is constantly turning, with oil flowing through the system and with a valve that opens at the required pressure to re-pressurise the accumulator; off-which the system relies to maintain pressurisation. This 7 piston pump is driven by the camshaft. So, in other words, the pump is constantly turning, most of the time under no pressure.

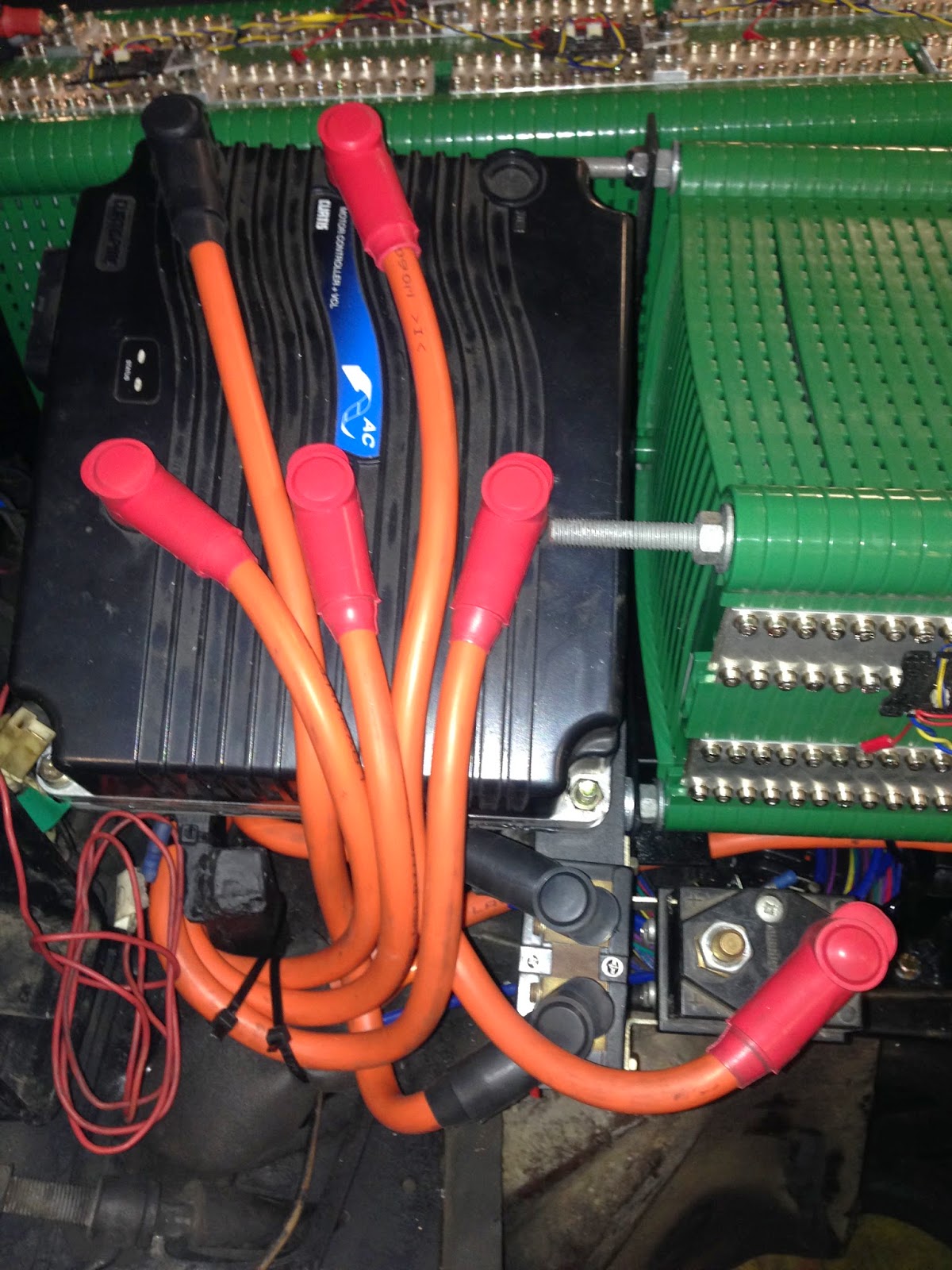

Being electric, we needed to save as much battery power as possible, so a constantly powered second motor (not the main propulsion motor), but a small high-torque unit, was not ideal. We re-engineered the system to include a high-pressure (around 1000psi) pressure-switch that at the right pressure, turned-off the electric motor and restarted it as the pressure fell to the lower-limit of pressure required.

So that "grinding" noise is a little, low-rev, high-torque motor that cuts-in at the right moment to repressurise the accumulator, maintaining the system at optimal pressure, under any condition.

And yes, the magnificent 1974 Citroen DSev is still running great (not without ongoing enhancements) and is now being prepared to travel overseas for European touring.

Well, glad you ask, and now take a seat and get prepared to be bored to tears.......

The Hydropneumatic (no it's not air) suspension that Citroen developed in the 40's and that saw it's full deployment in all its glory in 1955 on the Citroen DS (like the one in this Blog), was a true marvel of engineering; that it also powered the brakes, power-steering (yes, in 1955) and c-matic (manual-clutchless transmission) adds to its awe.

It is a constant flow system, that is, the pump is constantly turning, with oil flowing through the system and with a valve that opens at the required pressure to re-pressurise the accumulator; off-which the system relies to maintain pressurisation. This 7 piston pump is driven by the camshaft. So, in other words, the pump is constantly turning, most of the time under no pressure.

Being electric, we needed to save as much battery power as possible, so a constantly powered second motor (not the main propulsion motor), but a small high-torque unit, was not ideal. We re-engineered the system to include a high-pressure (around 1000psi) pressure-switch that at the right pressure, turned-off the electric motor and restarted it as the pressure fell to the lower-limit of pressure required.

So that "grinding" noise is a little, low-rev, high-torque motor that cuts-in at the right moment to repressurise the accumulator, maintaining the system at optimal pressure, under any condition.

And yes, the magnificent 1974 Citroen DSev is still running great (not without ongoing enhancements) and is now being prepared to travel overseas for European touring.